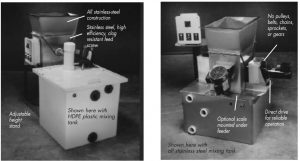

Eagle Microsystems VF-100 Volumetric Helical Screw Feeder for Dry Chemicals

The VF-100 provides more of what you want: better accuracy, higher reliability, longer life, more durable construction – and less of what you don’t what: maintenance – no lubrication, greasing or oiling is required , no belts, gears, sprockets, or chains to maintain. The VF-100 is simple, reliable and hassle-free.

VF-100 Volumetric Feeders are designed specifically to meet the requirements of the water and wastewater treatment industry, and finds application as well in the chemical, pulp and paper, and other industries – providing accurate, reliable dry chemical feed in even the harshest environments.

Key Benefits

- Rugged direct drive mechanism for reliable operation The VF-100 uses a direct-drive, variable speed, TENV dc gear motor for simple, reliable, dependable operation.

- Stainless steel construction for high corrosion resistance. All stainless steel construction in critical areas – hopper, base, feed screw, and trough – results in long life and reliable operation.

- No greases, oils, or other lubricants required. The use of durable plastic bearings and bushings eliminates the need for greases, oils, or other lubricants. This means no contamination of your dry chemicals, and no clumps or clogs to deal with, for cleaner operation with minimal maintenance.

- Sensible, straightforward construction All components are easily accessible and, if necessary, can be replaced with a minimum of disassembly using common wrenches and hand tools.

- Accurate, reliable feed rate control. Maximum feed rates from 0.04 to 17 cubic feet per hour are further controlled by varying the speed of the motor using a state-of-the-art electronic SCR speed control, resulting in 2% or better accuracy with free flowing materials. A 30:1 turndown provides a wide range of speeds for the selected drive, while maintaining required torque throughout the operating/feed range. And should there ever be a clog of obstruction, the current limiting circuitry will turn off the unit before any damage occurs.

Optional Mixing tanks for reliable, simplified solution makeup

Mixing tanks are available in configurations and materials to meet your specific needs. Select from HDPE plastic or all stainless steel, with downspout, mixer, and other useful accessories in the configuration that matches your application.

Contact Us For Pricing Today

Hawkins is a business-to-business supplier, manufacturer, blender, and distributor of chemicals. We do not to individuals.