Blue – White Pumps

Blue-White Pumps make water cleaner and safer for all economic regions and applications. From rural water sources to high density city-scapes, Blue-White continues to develop pumps ranging from basic to sophisticated for a diverse range of application challenges.

(Click on the meter picture below for more info)

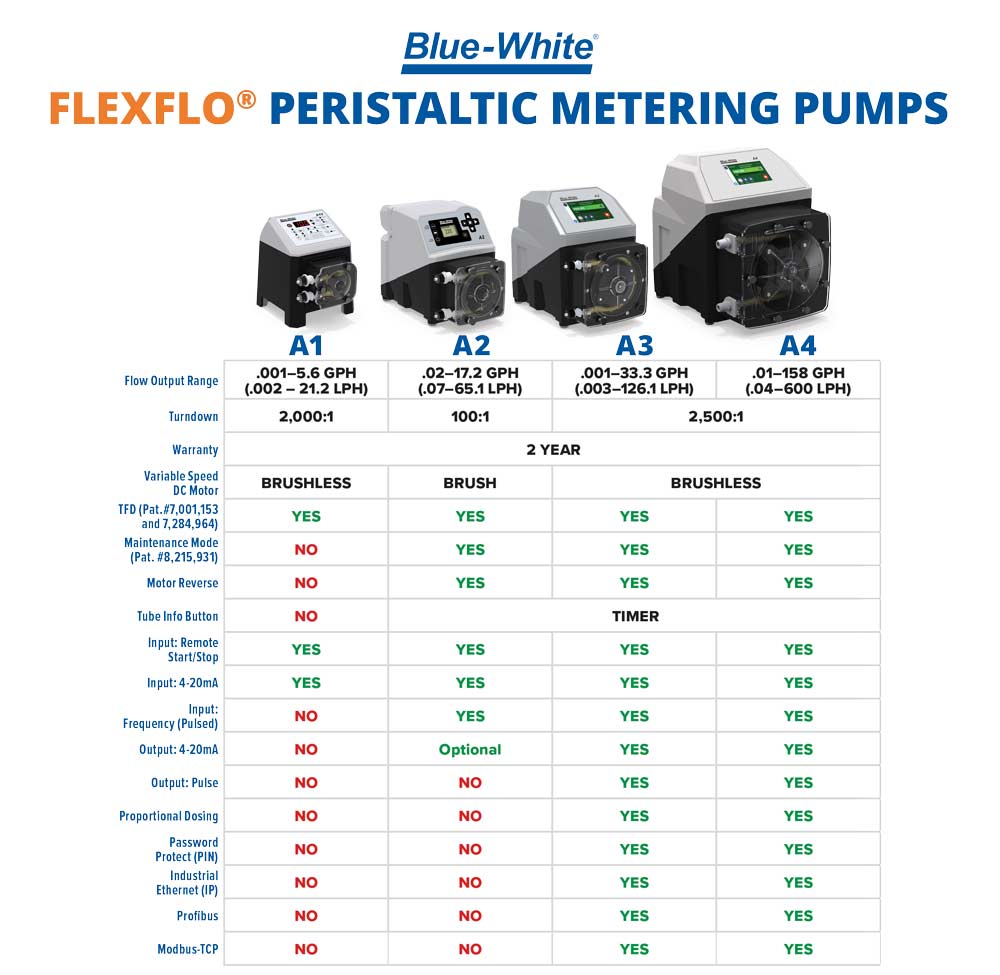

Blue – White Peristaltic Metering Pumps

Blue-White’s FLEXFLO® Series of Peristaltic Metering Pump are designed to dose precise amount of chemical; and FLEXFLO® pumps will not experience vapor lock or loss of prime. Each pump comes with built in Tube Failure Detection, which will prevent dangerous chemical spills and downtime.

Blue-White A1 – FLEXFLO® Peristaltic Metering Pump

The Blue-White FLEXFLO® A1 Peristaltic Metering Pump delivers reliable chemical feed with simple-to use-controls and precise adjustability. Ideally suited for low to medium flow applications, this compact and rugged self-priming pump delivers smooth chemical feed and does not require check valves or seals that can clog, leak, or corrode. Cannot vapor lock or lose prime.

Capabilities:

- Output rates to: .003 – 5.6 GPH (.011 – 21.2 LPH) and pressures to 100 PSI (6.89 Bar).

Superior Engineered Design:

- CNC precision-machined squeeze rollers for optimum squeeze, unparalleled accuracy, and tube life

- Heavy-duty rotor – single piece plastic rotor means no flexing and increased accuracy with no metal springs or hinges to corrode

- Energy-efficient brushless DC motor

- Specially engineered tubing for long life

Blue-White A2 FLEXFLO® Peristaltic Metering Pump

Simplify chemical feed with the Blue-White FLEXFLO® A2 Peristaltic Metering Pump. This rugged and compact pump features a gentle, low-shear pumping action, making it an ideal choice for dosing shear-sensitive or gaseous fluids. The A2 does not require check valves, seals, or other ancillary equipment to function, reducing maintenance intervals and process downtime. Remote control signal options include Remote Start/Stop, Flow Verification, Pulse, and 4-20mA.

Benefits:

- Self-priming – even against maximum line pressure. By-pass valves are not required. Cannot vapor lock or lose prime. 30ft of suction lift. Gentle low shear pumping action

- Tube Failure Detection (TFD) senses tube rupture by detecting chemical in the pump head. No false triggering – Patented

- Operator friendly digital controls with backlit LCD displays motor speed, input signal values, service, and alarm status

Blue White A3 FLEXFLO® Peristaltic Metering Pump

Experience next-level chemical metering with the Blue White FLEXFLO® A3 Peristaltic Metering Pump. The A3 combines accurate metering at discharge pressures up to 125 PSI, intuitive icon-based touch screen controls, and IP rated M12 connection ports that protect against moisture, dust, vibration, and any temperature change.

A3V remote control signal options include Pulse, 4-20mA, Modbus TCP, EtherNet IP, and PROFIBUS for enhanced supervision and automation for critical metering and transfer applications.

Benefits:

- Self-priming – even against maximum line pressure. By-pass valves are not required. Cannot vapor lock or lose prime. 30ft of suction lift. Gentle low shear pumping action

- Tube Failure Detection (TFD) senses tube rupture by detecting chemical in the pump head. No false triggering – Patented

- 5” touchscreen color LCD display

Blue-White FLEXFLO® A4 Peristaltic Metering Pump

Experience next-level chemical metering with the Blue-White FLEXFLO® A4 Peristaltic Metering Pump. The A4 combines accurate metering at discharge pressures up to 125 PSI, intuitive icon-based touch screen controls, and IP rated M12 connection ports that protect against moisture, dust, vibration, and any temperature change.

A4V remote control signal options include Pulse, 4-20mA, Modbus TCP, EtherNet IP, and PROFIBUS for enhanced supervision and automation for critical metering and transfer applications.

Benefits:

- Self-priming – even against maximum line pressure. By-pass valves are not required. Cannot vapor lock or lose prime. 30ft of suction lift. Gentle low shear pumping action

- Tube Failure Detection (TFD) senses tube rupture by detecting chemical in the pump head. No false triggering – Patented

- 5” touchscreen color LCD display

- 2,500:1 turndown ratio

- Heavy duty rotor means no flexing and increased accuracy with no metal springs or hinges to corrode

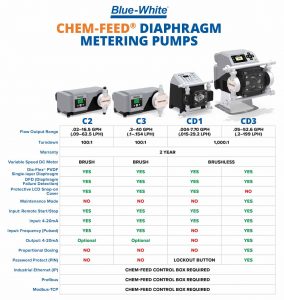

Diaphragm Pumps

Blue-White’s CHEM-FEED® Diaphragm Pumps reliably feed chemicals in high-pressure industrial applications with minimal downtime.

Blue-White C2 CHEM-FEED® Diaphragm Metering Pump

The Blue-White CHEM-FEED® C2 Diaphragm Metering Pump delivers accurate chemical feed quietly and efficiently against high system pressures. With an easy-to-read LCD user interface and optional pulse/frequency/4-20 mA input capability, the CHEM-FEED® C2 pump has the power and flexibility you need to take control of your fluid management process.

Benefits:

- DiaFlex® diaphragm design will last the life of the pump, eliminates the need for expensive rebuild kits – Patented

- Diaphragm Failure Detection (DFD) built-in leak detection comes standard

- Accurate chemical metering with pressures of up to 175 PSI

- Operator friendly digital controls with backlit LCD displays motor speed, input signal values, service, and alarm status

- 100:1 turndown ratio

- Alarm relay monitors the DFD system and FVS system

- Diaphragm Failure Detection (DFD) Senses diaphragm rupture by detecting chemical in the pump head. No false triggering – Patented

Blue-White C3 CHEM-FEED® Diaphragm Metering Pump

The Blue-White CHEM-FEED® C3 Diaphragm Metering Pump delivers accurate chemical feed quietly and efficiently against high system pressures. With an easy-to-read LCD user interface and optional pulse/frequency/4-20 mA input capability, the CHEM-FEED® C3 pump has the power and flexibility you need to take control of your fluid management process.

Benefits:

- DiaFlex® diaphragm design will last the life of the pump, eliminates the need for expensive rebuild kits – Patented

- Diaphragm Failure Detection (DFD) built-in leak detection comes standard

- Accurate chemical metering with pressures of up to 150 PSI

- Operator friendly digital controls with backlit LCD displays motor speed, input signal values, service, and alarm status

- Alarm relay monitors the DFD system and FVS system

- Diaphragm Failure Detection (DFD) senses diaphragm rupture by detecting chemical in the pump head. No false triggering – Patented

- UV display cover protects controls from harsh environments

Blue-White CD1 CHEM-FEED® Multi-Diaphragm Metering Pump

The CD1 Multi-Diaphragm Metering Pump delivers smooth, continuous chemical feed even when injecting chemicals that off-gas like Peracetic Acid and Sodium Hypochlorite. The cutting-edge Hyperdrive Technology allows for alternating pumping action between two diaphragms: when one diaphragm is in the suction phase, the other is in the discharge, resulting in a smooth chemical feed profile and eliminating the chance of vapor lock.

Benefits:

- Exclusive Hyperlink Drive technology allows for smooth chemical feed – Patent Pending

- Dual Diaphragm with full stroke technology will not lose prime, ideal for pumping chemicals that off-gas (Peracetic Acid, Sodium Hypochlorite)

- Can pump chemicals continuously, like a peristaltic pump, without the need for tube assemblies

- The CD1’s exclusive DiaFlex® Diaphragms will last the life of the pump, eliminating the need for expensive rebuild kits

- Diaphragm Failure Detection (DFD) Senses diaphragm rupture by detecting chemical in the pump head. No false triggering – Patented

Blue-White CD3 CHEM-FEED® Multi-Diaphragm Metering Pump

The CD3 Multi-Diaphragm Metering Pump delivers smooth, continuous chemical feed even when injecting chemicals that off-gas like Peracetic Acid and Sodium Hypochlorite. The cutting-edge Hyperdrive Technology allows for alternating pumping action between two diaphragms: when one diaphragm is in the suction phase, the other is in the discharge, resulting in a smooth chemical feed profile and eliminating the chance of vapor lock and loss of prime.

Benefits:

- Exclusive Hyperlink Drive technology allows for smooth chemical feed – Patent Pending

- Dual Diaphragm with full stroke technology will not lose prime, ideal for pumping chemicals that off-gas (Peracetic Acid, Sodium Hypochlorite)

- Can pump chemicals continuously, like a peristaltic pump, without the need for tube assemblies

- The CD3’s exclusive DiaFlex® Diaphragms last the life of the pump, ensuring virtually maintenance-free chemical feed

- Operator friendly digital touch pad with menu driven software

Blue-White C-1500N CHEM-FEED® Diaphragm Metering Pump

C-1500N Series Injectors feature Blue-White’s exclusive heavy-duty head with cartridge valves constructed of PVDF. Each valve has two ceramic checks and is double sealed. The double ball valve design provides enhanced priming and is exceptional for purging air and gas. The heavy-duty head is nearly maintenance-free, and bottom and top valves are completely interchangeable for quick, easy, and economical servicing.

Blue-White offers two distinct models: The Standard Model features a quick adjusting, high accuracy mechanical stroke length control. Deluxe Models feature stroke length and electronic time interval control.

Fixed Speed Diaphragm Pump

- Economical and versatile

- Max Feed: 9.5 GPH (36 LPH)

- All ball bearing, permanently lubricated gear motor for smooth, quiet, powerful operation

- Stroke adjustment from 5-100% permits accurate small injections at a high rate per minute

Output Control Options:

- Standard Models feature a quick adjusting, high accuracy mechanical stroke length control. The pump’s efficient design allows for a minimum stroke length of 5%. The Minimum recommended output is 5% of the maximum.

- Deluxe Models feature stroke length and electronic time Interval control. The pump’s on time is adjustable from 5-100% of the repeating 5 second time interval. (0.25 – 5.0 sec.) The high frequency of the repeating 5 second time interval, and the extremely accurate mechanical stroke adjustment, resulting in a higher frequency of small injections per minute. The Minimum recommended output is .5% of the maximum.

Construction

- Outdoor rated enclosure

- Durable housing of chemical resistant Val ox (PBT) thermoplastic

- PTFE coated EP diaphragm

- Double-ball inlet and outlet cartridge type ceramic check valves. Chemical resistant PVDF valve body and fitting, ceramic balls, Viton static seals, and TFE/P ball seat o-rings

- No metal springs are used

Blue-White C-600P CHEM-FEED® Diaphragm Metering Pump

The CHEM-FEED® C-600P Diaphragm Metering Pump is a simple and economical solution to a wide range of commercial and industrial fluid process applications. This compact pump features an all-ball bearing, permanently lubricated gear motor for smooth, powerful, and quiet operation. Stroke adjustment from 4-100% permits accurate small injections at a high rate per minute.

Benefits:

- All ball bearing, permanently lubricated gear motor for smooth, quiet, powerful operation

- Double-ball inlet and outlet cartridge type ceramic check valves. Chemical resistant PVDF pump head, valve body and fittings, ceramic balls, FKM static seals and TFE/P ball seat o-rings. No metal springs are used

- Outputs to 516 GPD

- Output pressures to 125 PSI

- Stroke adjustment from 4-100% permits accurate small injections at a high rate per minute. 27:1 turndown

- PTFE coated Ethylene Propylene diaphragm can handle a wide variety of applications

- Durable metal epoxy coated construction

Blue-White C-600HV CHEM-FEED® Diaphragm Metering Pump

The CHEM-FEED® C-600HV (High Volume) Diaphragm Metering Pump is a simple and economical solution to a wide range of commercial and industrial fluid process applications. This compact pump features an all-ball bearing, permanently lubricated gear motor for smooth, powerful, and quiet operation. Stroke adjustment from 4-100% permits accurate small injections at a high rate per minute.

Benefits:

- All ball bearing, permanently lubricated gear motor for smooth, quiet, powerful operation

- Solid, clear acrylic pump head with large high-output diaphragm

- Ethylene Propylene diaphragm can handle a wide range of demanding applications

- Outputs to 1130 GPD

- Output pressures to 20 PSI

- Stroke adjustment from 4-100% permits accurate small injections at a high rate per minute. 27:1 turndown

- Durable metal epoxy coated construction.

Addition Water Treatment Solutions:

Delivering The Quality Service You’re Looking For

Our drivers are skilled technicians trained to provide on-the-spot service with the ability to troubleshoot and repair chemical feed equipment in the field.

An inventory of parts and loaner feed equipment are available on our delivery trucks, if needed.

Hawkins and your Sales/Service Representative are available 24 hours a day, 365 days a year to meet your needs. Hawkins has and will continue to aid customers with emergencies that could occur.