Jesco Solenoid-Diaphragm Dosing Pumps

Diaphragm dosing pumps are leak-free, and are therefore suitable for highly aggressive or toxic media. Depending on the gear type, the diaphragm allows pressures up to 16 bar.

MAGDOS Pumps

MAGDOS LB – Simple dosing pump in newest generation

MAGDOS LB – Simple dosing pump in newest generation

The MAGDOS LB solenoid-diaphragm dosing pump is a good-value alternative for simple and continuous dosing tasks. It is especially suitable for water treatment and the process industry. MAGDOS LB is available for seven capacity ranges. Double-ball valves ensure an accurate dosing. The dosing capacity can be adapted continuously from 0 – 100% through the stroke frequency. MAGDOS is a compact solution which only includes the most important elements for reliable dosing.

- Capacity range from 0.09 to 4.00 gph, max. back pressure 232 psig

- Wide-range power supply unit 110 – 240 V, 50/60 Hz, IP65

- Dosing head ventilation

- Suitable for wall and floor mounting

- Material finishes PVC, PP, PVDF

- Infinitely variable dosing rate from 0 – 100 %

- CSA and UL certified

MAGDOS LD – Simple to use and space-saving

MAGDOS LD – Simple to use and space-saving

MAGDOS LD plays an important role in the reliable and accurate dosing of liquids in process sequences and is available in seven power ranges. Double-ball valves ensure accurate dosing. To adapt the dosing performance, the stroke frequency can be adjusted manually or via an external control contact. The dosing pump is compact and, thanks to the small mounting area, can be integrated into every dosing system in a very space-saving way. It can be mounted in three different positions without further attachments: standing, left- or right-oriented on a wall.

- Capacity range from 0.09 to 4.00 gph, max. back pressure 232 psig

- Power supply 230 V ±10 %, 50/60 Hz, IP65 or 115 V ± 10 %, 50/60 Hz

- Dosing head ventilation

- Suitable for wall and floor mounting

- Material finishes PVC, PP, PVDF

- Stroke frequency can be precisely adjusted via the keyboard

- Graphic display

- Pulse input (increase and reduction)

- Level input with early warning and main alarm

- Release input for external start/stop

- Calculation wizard for pulse operation available online

- CSA and UL certified

MAGDOS LA – Simple to use and space-saving

MAGDOS LA plays an important role in the reliable and accurate dosing of liquids in process sequences and is available in seven power ranges. Double-ball valves ensure accurate dosing. To adapt the dosing performance, the stroke frequency can be adjusted manually or by an analogue input signal (0/4 – 20 mA). The dosing pump is compact and, thanks to the small mounting area, can be integrated into every dosing system in a very space-saving way. It can be mounted in three different positions without further attachments: standing, left- or right-oriented on a wall.

- Capacity range from 0.09 to 4.00 gph, max. back pressure 232 psig

- Power supply 230 V ±10 %, 50/60 Hz, IP65 or 115 V ± 10 %, 50/60 Hz

- Dosing head ventilation

- Suitable for wall and floor mounting

- Material finishes PVC, PP, PVDF

- Stroke frequency can be precisely adjusted via the keyboard

- Graphic display

- Analogue Input settable 0/4 – 20 mA

- Level input with early warning and main alarm

- Release input for external start/stop

- CSA and UL certified

MAGDOS LK – Simple to use and space-saving

MAGDOS LK – Simple to use and space-saving

MAGDOS LK plays an important role in the reliable and accurate dosing of liquids in process sequences and is available in seven power ranges. Double-ball valves ensure accurate dosing. To adapt the dosing performance, the stroke frequency can be adjusted manually or via an external control contact. The MAGDOS LK doesn’t just impress with its elegant design; the graphical display with a multi-language menu as well as the dosing pump’s operation using the integrated keyboard simplifies its use.

- Capacity range from 0.09 to 4.00 gph, max. back pressure 232 psig

- Power supply 230 V ± 10 %, 50/60 Hz, IP65 or 115 V ± 10 %, 50/60 Hz

- Dosing head ventilation (plastic version)

- Suitable for wall and floor mounting

- Material finishes PVC, PP, PVDF and stainless steel

- Stroke frequency can be precisely adjusted via the keyboard

- Graphic display with multi-language menu

- Pulse input (increase and reduction)

- Level input with early warning and main alarm

- Release input for external start/stop

- Supply amount displayed in various units

- Maximum delivery rate can be limited

- Energy-saving “Eco-mode” is available

- Stroke feedback output

- CSA and UL certified

MAGDOS LP – Simple to use and space-saving

MAGDOS LP is available in seven power ranges. Double-ball valves ensure accurate dosing. The dosing power can be adapted by varying the stroke frequency manually, via an external control contact or using a 0/4 – 20 mA signal. The MAGDOS LP is also available with an optional Ethernet interface. This network connection enables you to control the stroke frequency and the number of strokes. In addition, all error messages can be transmitted in the opposite direction.

- Capacity range from 0.09 to 4.00 gph, max. back pressure 232 psig

- Wide – range power supply unit 110 – 240 V, 50/60 Hz, IP65

- Dosing head ventilation (plastic version)

- Suitable for wall and floor mounting

- Material finishes PVC, PP, PVDF and stainless steel

- Stroke frequency can be precisely adjusted via the keyboard

- Graphic display with multi-language menu

- Analogue input and pulse input (increase and reduction)

- Level input with early warning and main alarm

- Release input for external start/stop

- Supply amount displayed in various units

- Maximum delivery rate can be limited

- Energy-saving “Eco-mode” is available

- Stroke feedback output

- Alarm relay output

- Batch dosing with interval and timer functions

- Dosing control input

- Diaphragm failure input for leak monitoring

- Ethernet interface (optional)

- CSA and UL certified

MAGDOS DE – Reliable dosing of chemicals

MAGDOS DE – Reliable dosing of chemicals

Solenoid-diaphragm dosing pumps play an important role in the reliable and accurate dosing of liquids in the process cycles. They are appropriate for low-pressure applications and small dosing quantities. Dosing pumps are used in many branches of industry that work with liquid chemicals – not excluding toxic and aggressive media.

- Capacity range from 4.7 to 27.7 gph, up to 150 psig

- Suitable for toxic and aggressive media

- Stroke length adjustable 0 – 100 %

- Stroke frequency adjustable 0 – 100 %

- DE 20 – 100: 0 – 70 /min.

- Switchable to external control (e.g. water meter)

- DE 20 – 100: up to 70 pulse/min.

- Pulse and level control input electrically isolated

- Connection for level control (pre- and main alarm)

- Warning alarm relais and/or digital display (optional)

- Double-ball valves for highest accuracy

- All types are available for German standard DVGW-DIN 19635

- 115 V model CSA proofed available

MAGDOS DX – Reliable dosing of chemicals

Solenoid-diaphragm dosing pumps play an important role in the reliable and accurate dosing of liquids in the process cycles. They are appropriate for low-pressure applications and small dosing quantities. Dosing pumps are used in many branches of industry that work with liquid chemicals – not excluding toxic and aggressive media.

- Capacity range from 4.7 to 27.7 gph, up to 150 psig

- Suitable for toxic and aggressive media

- Stroke length adjustable 0 – 100 %

- Stroke frequency adjustable

- DX 20 – 100: 0 – 70 /min.

- Switchable to external control (e.g. water meter)

- DX 20 – 100: up to 70 pulse/min.

- Switchable to external control with 0/4 – 20 mA input

- Pulse multiplication/division 1,2,4,8,16,32,64

- Pulse and level control input electrically isolated

- Warning alarm relais and/or digital display (optional)

- Connection for level control (pre- and main alarm)

- Double-ball valves for highest accuracy

- All types are available for German standard DVGW-DIN 19635

- 115 V model CSA proofed available

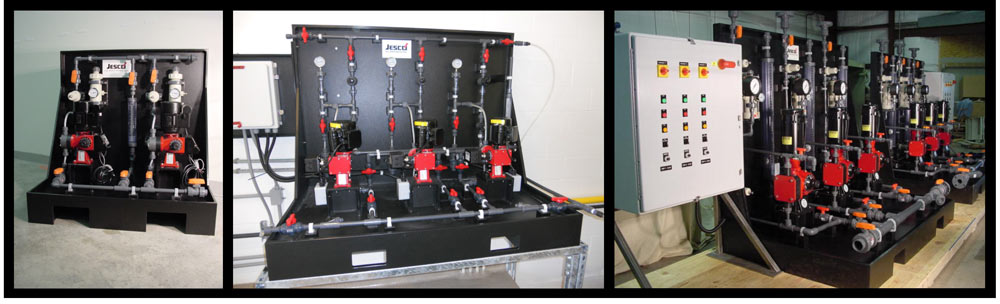

Jesco Skid Systems

Implementation of Systems and Processes

Composed of standard dosing components, the skid system is a cost-effective unit preassembled and tested prior to shipment. It arrives at your facility ready-to-go.

Simply put: Efficiency in a Box!

- Individual solutions

- Implementation of systems and processes

- Consisting of custom and standard dosing elements, together with the customer system solutions are developed for various processes.

MEMDOS Pumps

Motor-driven Diaphragm Dosing Pumps

Diaphragm dosing pumps are leak-free, and are therefore suitable for highly aggressive or toxic media. Depending on the gear type, the diaphragm allows pressures up to 16 bar.

MEMDOS E – Classic motor-driven diaphram dosing pump

MEMDOS E – Classic motor-driven diaphram dosing pump

The MEMDOS E combines the properties of the MEMDOS series working reliably for many years with the latest requirements in dosing technology. Two models of the MEMDOS are available. The smaller version can be used for capacities from 0…4 to 0…160 l/h and the larger version for capacities from 0…160 to 0…380 l/h. Pressures are admissible between 4 and 10 bar, depending on the size.

- Suitable for accurate mixing tasks

- Capacity range from 1.2 to 92 gph, max. back pressure 150 psig

- Linear development of the dosing quantity

- According to the stroke length

- Tappet drive with manual and automatic capacity adjustment

- Wide range of dosing head materials

- Double-diaphragm system optional

- Small stand, requires little space

MEMDOS DX – Electronic motor-driven diaphragm dosing pump

MEMDOS DX – Electronic motor-driven diaphragm dosing pump

The microprocessor-based MEMDOS DX combines the properties of the MEMDOS series with the latest requirements in dosing technology. Two models are available. The smaller version can be used for capacities from 0…4 to 0…160 l/h and the larger version from 0…380 l/h. Pressures are admissible between 4 and 10 bar. The MEMDOS DX is used if the pump is to be integrated in controls or automatic control systems. It allows the adaption to a large number of different control signals and system monitoring equipment.

- Suitable for accurate mixing tasks

- Capacity range from 1.2 to 92 gph, max. back pressure 150 psig

- Minor dependence of the back pressure

- Linear development of the dosing quantity

- According to the stroke length

- Wide range of dosing head materials

- Double-diaphragm system optional

- Small stand, requires little space

- Network connection optional

- Batch dosing optional

MEMDOS LB – Riding on the crest of the waves

The MEMDOS LB is used when the integration of the pump into controls or control circuits is required. Thanks to the sturdy tappet drive with manual or automatic capacity adjustment, the conveyed media such as acids, lyes, coagulants and flocculants are dosed reliably and precisely. To adapt the dosing capacity, either the stroke length can be adjusted mechanically or the speed of the three-phase motor can be regulated by means of a separate frequency converter. On request, the MEMDOS LB pumps can also be supplied with a double-diaphragm system.

- Capacity range 1.06 – 324 gph, up to 232 psig

- Power supply 115 V, 230 V or 400 V

- Material finishes PVC, PP, PVDF and stainless steel

- Infinitely variable stroke length from 0 – 100 %

- A variety of three-phase and alternating current motors

- ATEX versions are available for Zones 1 and 2

- Also suitable for frequency converter operation

- Double-diaphragm system (optional)

- Automatic stroke length adjustment (optional)

MEMDOS LA – Riding on the crest of the waves

The MEMDOS LA is equipped with a diverse range of inputs and outputs and can thus be deployed for complex dosing tasks. It can be controlled via a 0/4 – 20 mA current input and an external release input. At the same time, it indicates its current operating state via a fault output (alarm relay) and an optocoupler output (stroke feedback). The pump is fitted with a 0 – 20 mA analogue output.

The MEMDOS LA is compatible with all conventional control systems.

The pump is also fitted with a level input, can evaluate suction lines directly using a low level alarm and its large functional scope means that it can be deployed in a number of areas.

- Capacity range up to 270 gph, up to 232 psig

- Power supply 115 / 230 V, ± 5 %, 50/60 Hz

- Material finishes PVC, PP, PVDF and stainless steel

- Stroke frequency manually settable via a potentiometer

- Release input for external start/stop

- Analogue input 0/4 – 20 mA

- Level input with a switching point

- Analogue output 0 – 20 mA

- Alarm relay output

- Stroke feedback output

- Double-diaphragm system (optional)

- CSA and UL certified

MEMDOS LP – Riding on the crest of the waves

MEMDOS LP – Riding on the crest of the waves

The MEMDOS LP is used when the integration of the pump into controls or control circuits is required. For integration into demanding automation networks, a version with an Ethernet-based MODBUS interface is available. Thanks to the sturdy tappet drive with manual or automatic capacity adjustment, the conveyed media such as acids, lyes, coagulants and flocculants are dosed reliably and precisely. On request, the MEMDOS LP pumps can also be supplied with a double-diaphragm system.

- Capacity range from 1.1 to 270 gph, max. back pressure 232 psig

- Power supply 230 V, ± 5 %, 50/60 Hz

- Material finishes PVC, PP, PVDF and stainless steel

- Stroke frequency can be precisely adjusted via the keyboard

- Precise pump adjustment via the keyboard

- Graphic display with multi-language menu

- Analogue input 0/4 – 20 mA

- Pulse input (increase and reduction)

- Level input with early warning and main alarm

- Release input for external start/stop

- Supply amount displayed in various units

- Maximum delivery rate can be limited

- Stroke feedback output

- Batch dosing with interval and timer functions

- Dosing control input

- Alarm relay output

- Analogue output 0/4 – 20 mA

- Diaphragm rupture detection and reporting (optional)

- Double-diaphragm system (optional)

- Ethernet interface (optional)

MEMDOS MR / 2300 – Powerful motor-driven diaphragm dosing pump.

MEMDOS MR / 2300 – Powerful motor-driven diaphragm dosing pump.

Diaphragm dosing pumps of the MEMDOS MR / 2300 series have been developed for a broad range of applications. Thus they are used in the industrial sector, in process engineering and very frequently in water and waste water treatment. They are leakproof. Standard versions are with the head located on the left-hand side. dosing pumps with the head on the right-hand side can be supplied. Duplex dosing pumps are available with the head combinations shown in the following tables. The heads are arranged in diagonals.

- Capacity range from 17 to 310 gph (single head)

- Max. back pressure 150 psig

- PP and stainless steel dosing heads

- Double-ball valves (up to MR 290)

- Spring-loaded flat-seat valves (starts with MR 400)

- Spring-loaded single-ball valves (optional)

- Separation chamber between dosing head and gearbox, with drainage pipe

- Stroke adjustment either manually or electrically (ATE)

- Dublex head pumps (optional)

- Stroke counter with inductive detector for charge-processes (optional)

- Frequency converter controlling (optional)

MEMDOS GMR – Big motor-driven diaphragm dosing pump

Double diaphragm dosing pumps of the MEMDOS GMR series can be supplied as single or duplex dosing pumps. The pumps are used to meter large quantities at relatively low back pressures. They are frequently used in waste-water treatment to meter pH-regulating chemicals or flocculents.

- Double diaphragm dosing pump

- Single or duplex dosing head pump

- Capacity range from 82 to 1057 gph (single dosing head)

- Medium side of EPDM separating diaphragm coated with PTFE

- Single-ball valves

- Drive: AC or DC motor

- Stroke counter with inductive detector for charge-processes (optional)

- Frequency converter controlling (optional)

Addition Water Treatment Solutions:

Hawkins Is Where To Buy Water Treatment Equipment

Experience next-level service with customized water treatment solutions designed specifically for your facility. Our locally based, professionally trained technicians work with you to test, fine-tune, and optimize your current system ensuring you have the right equipment and chemistry for peak performance.

Partner with Hawkins — a trusted supplier for over 85 years.

Fill out the form below, and we’ll connect you with a sales rep who can help you with all your needs.