Brewery & Beverage Products Supplier & Distributor

Sanitizers, Cleaners, Acidulants, Waste Neutralization

and so much more

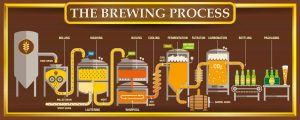

HOT SIDE OF BREWING PROCESS: HOT LIQUOR TANK, MASH / LAUTERING, BOIL KETTLE, WHIRPOOL

Hot Liquor Tank (Water)

Mash / Lautering

Boil Kettle

Whirlpool

COLD SIDE OF THE BREWING PROCESS:

HEAT EXCHANGER, FERMENTATION, FILTERING, BRIGHT TANK, SERVING TANK, PACKAGING, BARREL AGING

Cooling / Heat Exchangers

Fermentation Tank

Brite Tank / Serving Tank

Barrel

PACKAGING: BOTTLING, CANNING, KEGS

Bottling

Cleaning

Canning

Kegs

TAP ROOM: DRAFT SYSTEMS, SINKS, GROWLERS, FLOORS

Draft Systems

Acid Wash

Sinks

Growlers

Floors

Acid Wash

Sanitation

Peracetic Acid 5.6%

Peracetic Acid 15%

GO2 – Chlorine Dioxide

Sunburst QuickSan – Quats

Sanitizers

- GO2: Chlorine Dioxide, simple to use, two step kit. Final equipment rinse/container (keg, bottle, can) sanitizing

- Reflex: Acid sanitizer containing a combination of acids including 6.1% peroxyacetic acid

- Bleach: Strengths 4-15%

- Bioside HS 15: Peracetic acid 15%

Cleaners

- Customized functional blends and flavors

- Hawkins Cleaner NPB: Low foam acid CIP cleaner nitric and phosphoric acid to remove scale and beer stone

- Hawkins PC Cleaner: Low foam acid CIP cleaner phosphoric and citric acid to remove scale and beerstone – follow up to caustic cleaner

- Hawkins Peroxide Cleaner: Foaming peroxide cleaner 30%. Strong oxidizing cleaner good for tough cleaning challenges

- Hawkins Peroxide Cleaner 9%: Foaming peroxide cleaner 9%. Strong oxidizing cleaner good for tough cleaning challenges

- Hawkins Citric-Peroxide Cleaner: Low foam cleaner with citric acid, peroxide, quaternary ammonium compounds. Clean and prep canning, bottling and serving

- Hawkins Caustic Cleaner: High strength low foam CIP caustic cleaner

- Hawkins Caustic Cleaner 70: Mid strength low foam CIP caustic cleaner 70% of high strength

- Sodium Percarbonate: The main ingredient in powdered brewer wash and dry oxygen cleaners

- Hawkins Foaming Chlorinated Cleaner: High foaming cleaner with bleach

- Hawkins Beverage Equipment Cleaner: Foaming alkaline cleaner for the exterior of equipment

- Hawkins Beverage Equipment Brightener: Blended acid cleaner and metal brightener – high foam

- Hawkins Rinse Aid: Clean sheeting final rinse with chelating agents to keep minerals/metals in solution

Acidulants – High Purity Food Grade

- Citric Acid Dry 15-50%: Cleaning, passivating, adjunct for bright crisp finish (lager like) with very little sour

- Phosphoric Acid 20-75%: Acid cleaning – soda like souring

- Lactic Acid 50-88%: To replace lactobacillus souring

- Malic Acid Dry 50%: For crisp apple at low levels and sour apple at higher levels

- Acetic Acid 10-99.5%: To replace acetobacter souring

- Vinegar 300 Grain-30%: Natural acid to replace acetobacter souring

- Apple Cider Vinegar 10%: Natural acid to replace acetobacter souring

Waste Neutralization

- Sulfuric Acid: 10-93%

- Sodium Hydroxide: 10-50%

Premium Diatomaceous Earth Filter Aids – For the Brewing Industry

Transcend® Filtration Media Without Detectable Crystalline Silica

The better filter aid – for your products and your employees

Transcend®. It’s the revolutionary new filter aid that changes everything. No detectable Crystalline Silica. A drop-in replacement for your current filter aid. Most important: It’s what you’ve been waiting for to provide better products for your customers, and a better working environment for your employees. No detectable Crystalline Silica in your filtration– why would you want any other kind of filter aid?

Transcend. Patent pending. Produced with proprietary processing techniques. Transcend is the exclusive, engineered filter media derived from diatomaceous earth (DE) but with no detectable crystalline silica.

Why is Transcend the better filter aid?

• Dramatically reduce employee crystalline silica exposure, with $0 capital cost

• Comparable performance to Celatom DE filter media

• Drop-in replacement for conventional DE filter media

• Superior throughput & size exclusion, relative to perlite & cellulose filter media

Other

- Chill-Pro: Food Grade, Inhibited Propylene Glycol

Contact Us For Pricing Today!

Hawkins is a business-to-business supplier, manufacturer, blender, and distributor of chemicals. We only sell to companies, municipalities, government entities, and not to individuals.