Assmann Polyethylene Tanks

Assmann Plastic Chemical Storage Tanks – Bulk chemical storage tanks, in multiple sizes and shapes. Double walled and single walled and containment systems.

Assmann storage tanks are rotationally molded for chemical and corrosion resistance. These polyethylene chemical storage tanks are easier to position and more durable than anything else on the market.

Assmann storage tanks are used for above-ground bulk storage in industries like water and wastewater, industrial chemical, oil and gas, food processing, and more. Our tanks provide solutions for those looking to store industrial chemicals, water, agricultural chemicals, and oils

The Assmann polyethylene storage tanks difference: Assmann tanks are constructed by rotational molding, in a slow, steady, highly-regulated process. Our tanks are some of the only on the market to be ISO-certified and have been since 1997.

Designed to outlast the competition: This molding process results in a stronger mold without cutting any corners. We don’t use any pressure or heat to speed up the process, which leaves our tanks stress-free. While this lengthens our manufacturing time, it ensures that you get a product with quality that you never have to question.

The Assmann Polyethylene Tank Difference

It’s in the way they make their plastic storage tanks:

Assmann polyethylene storage tanks use a special rotational molding process that uses no pressure for stress free chemical storage tanks that creates a superior product. The Assmann tanks range from 40 to 12,000 gallons, engineered and processed for the most challenging chemical handling and storage applications. They begin by selecting resins with the best properties for the application based on their thirty plus years of molding and in-the- field experience.

Key Manufacturing Differences:

Rotational Molding of Polyethylene Tanks and Plastic Products: Assmann’s unique and efficient large ovens rotate end-over-end, and receive convection heat. The oven’s shape and foil design creates optimum airflow and uniform heat to set the first stage for the highest quality parts possible.

Cooling Without Water Allows Cross-Linking Process to Complete All The Way Through the Polytank Wall: Assmann has separate chambers using only very high volume air movement to assure a gradual cooling of the mold and the part inside. This allows the cross-linking process, still taking place upon exiting the oven chamber, to complete all the way through the tank wall. This is essential to optimize the properties of the cross-linked part. (The whole idea is to achieve as close to 100% cross-linking as possible). Assmann introduces no water into our cooling cycle. (Water spray or mist will speed up the process, but will abruptly stop the cross-linking and set up the stresses that will shorten the service life of the tank.)

Tooling Of Plastic Storage Tanks – Assmann Does Not “Shield” Tank Walls: Equally important in our process is that Assmann does not “shield” the outside of our tank molds. They exceed ASTM design hoop stress minimums for the lower sidewall and carry this wall thickness as uniformly as possible throughout the entire tank for maximum structural integrity.

Why is this important? It has become a common practice among Assmann’s competitors to wrap and weld layers of sheet metal (shielding) around the outside of the mold to reduce heat transfer and thereby reducing thickness. Upper sidewalls, domes and tank bottoms are often reduced to less than 25% of the thickness of the lower sidewall.

Some of the obvious consequences of this practice competitors use:

- There is greater damage when tank restraint systems are put to the test

- Tank domes may collapse, even under snow weight

- Stress cracking agents along with UV deterioration will accelerate dome failure

- Results in uneven cooking and significant variations in gel percentages over the tank structure

Assmann’s proven rotational molding process consistently produces a superior product.

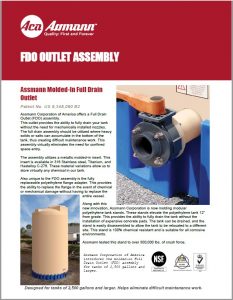

Molded In Full Drain Outlet – Patent Pending

Assmann also offers a unique FDO (Full Drain Outlet) outlet assembly. This outlet provides the ability to fully drain your tank without the need for mechanically installed nozzles. The full drain assembly should be utilized where heavy solids or salts can accumulate in the bottom of the tank thus creating difficult maintenance work. This assembly virtually eliminates the need for confined space entry.

The assembly utilizes a metallic molded in insert. This insert is available in 316 Stainless steel, Titanium and Hastelloy C-276. These material variations allow us to store virtually any chemical in our tank.

Also unique about the FDO assembly is the fully replaceable polyethylene flange adapter. The adapter can be removed so that the tank can be installed on a flat surface without concrete pad. This also provides the ability to replace the flange in the event of chemical or mechanical damage without having to replace the entire vessel.

Assmann Polyethylene Tanks are NSF Certified

- Assmann Corporation’s Crosslink Tanks are approved for chemical storage by NSF!

- Schulink XL-350 Crosslink Resin

- Assmann is the FIRST Crosslink Tank approved by NSF for chemical storage!

NSF is an independent testing company that requires Assmann Corporation of America to comply with strict standards. These standards require extensive product testing and material analysis. NSF undertakes a complete evaluation of our product development before we can meet their certification.

NSF / ANSI 61 program is responsible for the certification of drinking water treatment chemicals and drinking water system components to ensure that these products do not contribute contaminants to drinking water that could cause adverse health effects.

Assmann Corporation’s crosslink polyethylene tanks have been certified by NSF International to ANSI 61 standards for chemical storage. Assmann’s unique crosslink resin is certified for many chemical applications. Sodium Hypochlorite, Sulfuric Acid, and Sodium Hydroxide are within the list of chemicals our tanks can be used to store. For a complete list of certified chemicals, visit nsf.org.

In addition to our crosslink tanks for chemical storage, Assmann Corporation’s linear polyethylene tanks have been certified by NSF International to ANSI 61 standards for potable water. With both crosslink and linear polyethylene certifications Assmann Corporation can be your first source for both potable water & chemical storage for water treatment.

Assmann Corporation’s certification includes tank models ranging in size from 20 through 12,000 gallons.

Addition Water Treatment Solutions:

Contact Us For Pricing Today!